Why polyamide heat barriers are preferred in aluminum joinery and facade systems:

Superior chemical and mechanical strength, having a heat expansion coefficient very close to the thermal expansion coefficient of aluminum, perfect adaptation to temperature differences (from minus 40°C to + 220°C), high thermal insulation (heat conductivity value 0.23 W/K xm) Aluminum joinery works with expansion depending on the ambient temperature. Therefore, in order for the joinery not to deform, the polyamide thermal insulation barrier that connects the two aluminum profiles should show the same amount of expansion as the aluminum profile. Polyamide thermal insulation barrier has this feature. Since the 25 percent glass fiber reinforced Polyamide 6.6 thermal insulation barrier remains without any deformation at 200-210 °C for 20 - 25 minutes, it provides great convenience in the production of powder coated thermally insulated aluminum profiles, because in this way, after the aluminum profiles are combined with the thermal insulation barrier, the dust can be dyed.

Superior chemical and mechanical strength, having a heat expansion coefficient very close to the thermal expansion coefficient of aluminum, perfect adaptation to temperature differences (from minus 40°C to + 220°C), high thermal insulation (heat conductivity value 0.23 W/K xm) Aluminum joinery works with expansion depending on the ambient temperature. Therefore, in order for the joinery not to deform, the polyamide thermal insulation barrier that connects the two aluminum profiles should show the same amount of expansion as the aluminum profile. Polyamide thermal insulation barrier has this feature. Since the 25 percent glass fiber reinforced Polyamide 6.6 thermal insulation barrier remains without any deformation at 200-210 °C for 20 - 25 minutes, it provides great convenience in the production of powder coated thermally insulated aluminum profiles, because in this way, after the aluminum profiles are combined with the thermal insulation barrier, the dust can be dyed.

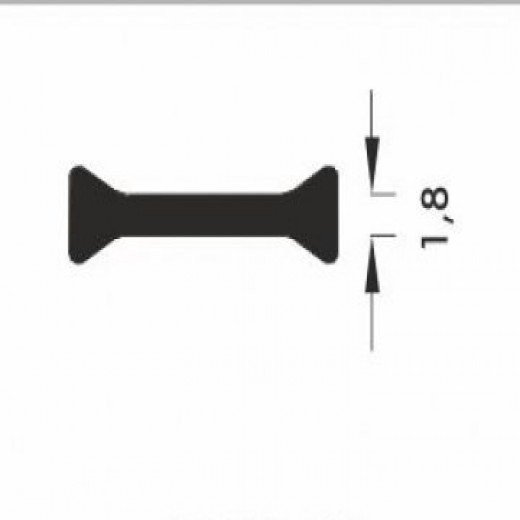

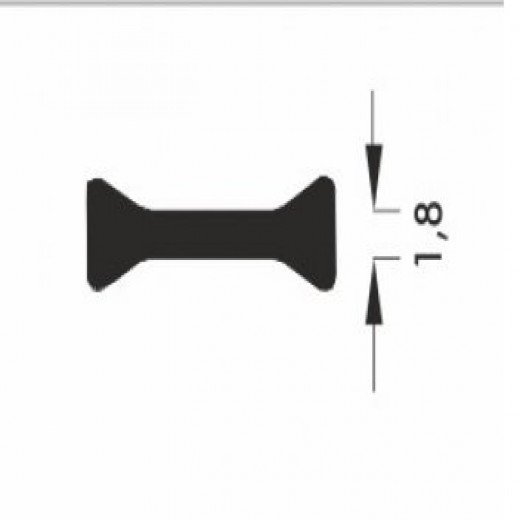

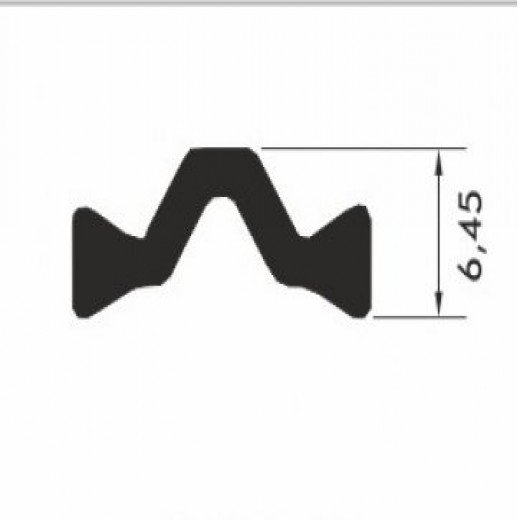

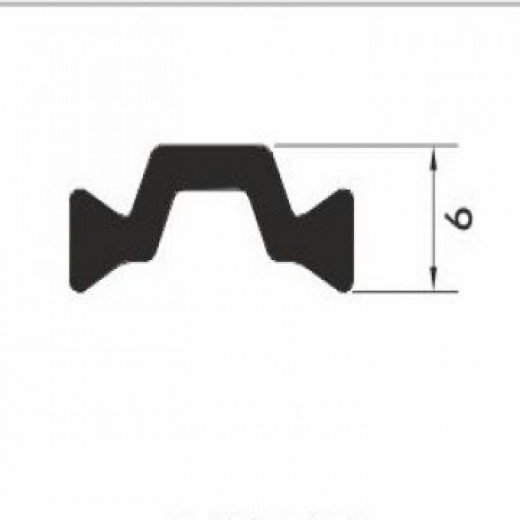

EPDM Gaskets

EPDM Gaskets

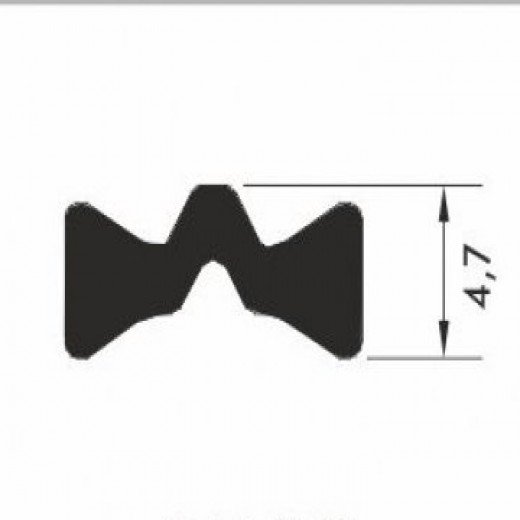

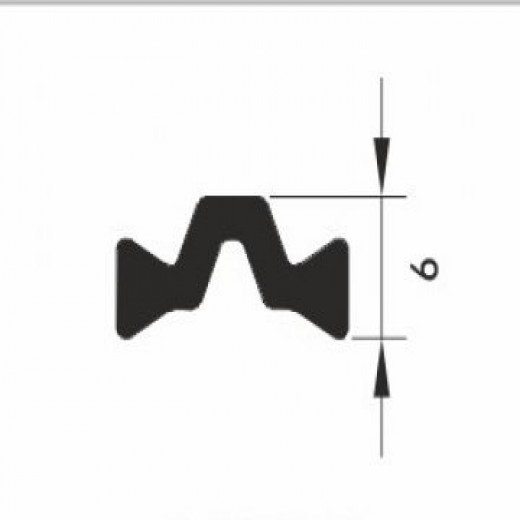

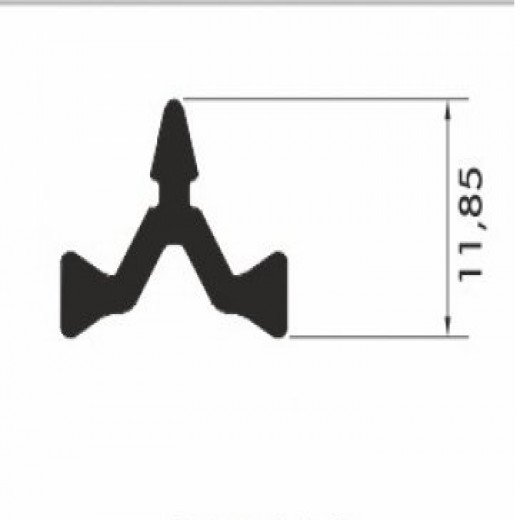

TPE Gaskets

TPE Gaskets

Polyamide Thermal Breaks

Polyamide Thermal Breaks